Back-Contact Solar Modules – Technological Advantages over PERC and TOPCon

- Oct 27, 2025

- 6 min read

Back-contact solar modules are an innovation by relocating all electrical contacts to the back of the cell. This eliminates the typical shading of the cell front caused by metal contacts. The result is homogeneous, deep matte black solar modules with measurably higher efficiency – currently 23.5% module efficiency and 27% cell efficiency. For limited or partially shaded roof areas, this leap in efficiency can represent a cost-effective solution.

How the back-contact solar modules work

With back-contact technology, referred to as "BC," all conductive paths are located on the back of the solar cell . Conventional modules, on the other hand, distribute their electrical contacts across the front and back, which inevitably shades part of the front surface for conductive paths.

Back-contact cells combine a metal-free front design with a more complex matrix-like contact architecture on the back. The front remains free—no metallic elements interfere with the incoming light.

This is technically implemented through a back-side layout of alternating p- and n-doped finger structures that are precisely laser-etched into the cell substrate. This laser patterning separates the contacts, optimizes current flow, and minimizes resistance. Current is completely dissipated on the back side, shortening the paths.

This leads to reduced conduction losses and lowers the risk of hotspots within the cell. In short: Back-contact cells feature a highly optimized cell architecture that combines maximum light yield and efficient current dissipation.

technology | Optics front | Efficiency | Temperature coefficient | Shading behavior |

PERC | silver conductor tracks visible | 21–22% | -0.35%/°C | subsceptible |

TOPCon | light busbars visible | 22–23% | -0.29%/°C | subsceptible |

Back-Contact | no conductor tracks visible | up to 23.8% | -0.26%/°C | very good |

Higher efficiency compared to PERC and TOPCon

A key feature of back-contact solar modules is their exceptionally high efficiency. Since there are no busbars or contact fingers on the front of the cell, no sunlight is lost through the front-facing metal strips . By comparison, in conventional PERC or TOPCon cells, the front-facing silver conductors block approximately 3–5% of the incident light.

Back-contact cells, on the other hand, utilize the entire cell surface for photon absorption. Furthermore, the local heating caused by front-facing metallization is eliminated because there are no front-facing busbars . In summary, back-contact technology can convert significantly more solar energy into electricity.

480Wp power on 2m²

No light-induced degradation (LID)

In addition, back-contact cells are usually based on n-type silicon wafers . N-type wafers offer higher charge carrier mobility and are less susceptible to contamination than p-type material. Furthermore, they exhibit virtually no light-induced degradation (LID), meaning performance doesn't degrade in the first few weeks of operation. Combined with passivation layers on both sides to reduce surface recombination, BC cells achieve cell efficiencies of over 27% in series production.

This means that BC modules deliver noticeably more power at high temperatures. These technical advantages make back-contact cells one of the most efficient cell architectures on the market.

The difference between BackContact and PERC, TOPCon and HJT

The efficiency advantage is also evident at the module level: While conventional PERC, TOPCon, or HJT modules currently achieve module efficiencies of around 21–23%,SOLYCO Back-Contact modules already achieve 23.5% .

This corresponds to approximately 30 W more power per module compared to current TOPCon models in the residential sector. Efficiencies of even over 25% are expected in the next generation. Especially where roof space is limited, BC modules thus allow for significantly higher kWp per square meter. In other words: more power on the same surface area means a higher system yield and often more economically attractive projects.

Better shading behavior and higher energy yield

SOLYCO BackContact modules are characterized by their superior behavior in partial shading - an important advantage, especially in residential and urban areas, where roofs are often partially shaded by dormers, chimneys or neighboring buildings. Even temporary dirt such as leaves, bird droppings or snow can lead to shading. With conventional solar modules, even the partial shading of individual cells can lead to the failure of an entire module string , as the affected cell interrupts the electrical circuit.

BackContact modules, on the other hand, have a finely structured cell structure with integrated bypass functionality at the cell level . This means that if part of a cell remains unshaded, this area can continue to produce electricity while the shaded part is bypassed. Unshaded cell areas remain active to a certain extent , instead of the entire module collapsing. This means that electricity still flows in so-called sub-strings even in partial shading, which significantly improves the overall yield .

Back-Contact in Practice

Practical tests in a wide range of climates confirm this advantage. Field trials have shown that, depending on the scenario, BC modules deliver 4–33% more energy yield than conventional modules. On heavily shaded roofs, the advantage can be even greater over the system's lifetime.

For installers, this means less dependence on ideal solar conditions , more flexible system design, and more satisfied end customers. Overall, back-contact modules score highly with a higher real energy yield , especially in suboptimal installation situations.

Fewer hotspots and higher reliability

Better shading tolerance comes with another advantage: fewer hotspots and therefore greater operational reliability. Hotspots are local overheating areas in a solar cell that can occur when cells are partially shaded or defective and are therefore subjected to current that they themselves no longer produce. In conventional cells, what is known as thermal breakdown only sets in at relatively high blocking voltages (around 10-20 V) . In this state, a very high current flows through the affected cell, which can lead to significant heating – in extreme cases even cell damage or fire hazard.

Back-contact cells, on the other hand, have much lower breakdown voltages of around 2-5 V. If a BC cell is forced into reverse operation (e.g. due to shading), it will therefore conduct current at a much lower voltage. This limits the current flow early on and prevents dangerous heat buildup. Bypass diodes only need to intervene when extensive shading occurs.

The bottom line for back-contact modules is that there is less energy loss due to the shutdown of entire strings and less thermal stress on the cells.

Fewer stress factors

Laboratory and field data support this effect: Under adverse conditions—such as the presence of leaves, dirt, or partial shading—BC modules exhibited hotspot temperatures up to 30°C lower than standard modules. The lower heat generation increases operational safety and protects materials. In the long term, plant operators benefit from greater reliability and a longer module lifespan , as thermal stress factors are minimized.

Aesthetics: All-black without compromise

In addition to technical performance data, the appearance of PV modules is playing an increasingly important role – especially in high-end residential construction and design projects . Back-contact modules impress with their consistently elegant appearance. Because no metallic conductors are visible on the front of the cells , a deep black, homogeneous module surface is created.

Neither silver busbars nor solder joints nor color differences detract from the overall appearance. Combined with black module glass and a black frame, this creates a sophisticated "full-black" look that blends harmoniously into modern architecture and sophisticated roofscapes.

5 advantages of back-contact modules for end customers:

More power on the same area : Up to 15% higher energy yield and 23.8% module efficiency.

Better yields with shading : Up to 33% more electricity with partially shaded roofs.

Maximum security : 30-year warranty and hotspots up to 30°C cooler.

Stable even in hot weather : –0.26%/°C temperature coefficient ensures better performance in summer.

Premium look : All-black modules blend elegantly into any architecture.

5 advantages of back-contact modules for solar installers:

More efficient roof use : +30 Wp per module reduces installation and material costs.

More flexible planning : Stable yields even with complex shaded roofs.

More quality promise : Less hotspot formation & most solid technology

Unique combination : Premium design + much better shading resistance through matrix connection instead of bypass diodes alone.

Why are back-contact solar modules more expensive than conventional solar modules?

The manufacturing process is significantly more complex—but not "absurdly" more complex than it was 10-20 years ago. Here's a simple diagram to compare the cells:

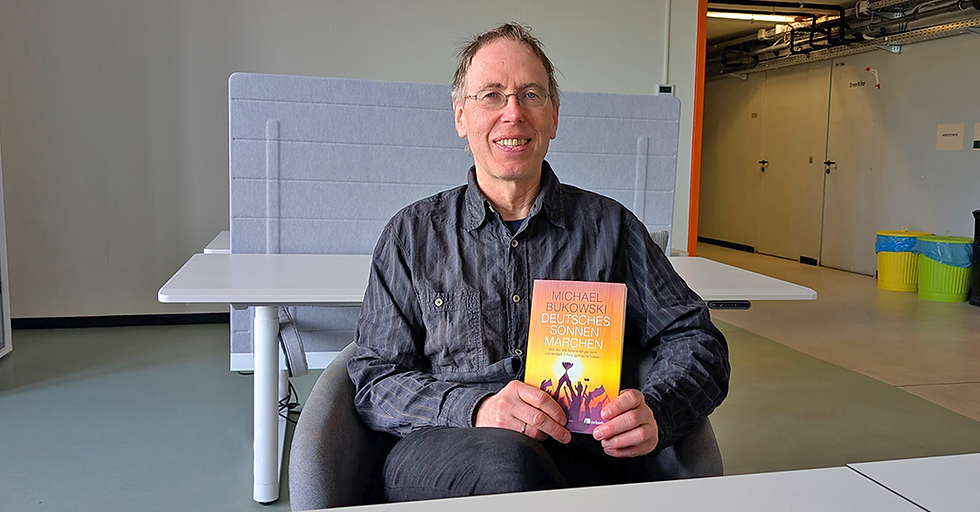

Back-Contact - The new thing? SOLYCO CTO in an interview.

Back-contact solar modules represent the next generation of PV module technology. Once considered a niche solution, the technology has made the leap into industrial mass production and established itself in recent years.

For installers, system planners, and technology-savvy end customers in the DACH region, this means that back-contact solar modules represent an extremely exciting option for photovoltaic systems.

FAQ

Why are back-contact solar modules more efficient than PERC, TOPCon and heterojunction?

No front metallization means no shading losses, >27% cell efficiency and better temperature behavior.

Are back-contact modules better in partial shading?

Yes. The internal cell bypass function keeps unshaded areas active, resulting in up to 33% higher yield in shaded areas.

How do BC modules prevent hotspots?

Low breakdown voltages (2–5 V) limit heat generation, with hotspot temperatures up to 30 °C lower.

Why are BC modules popular in premium residential construction?

High efficiency plus homogeneous full-black design for seamless architectural integration.

What warranty do SOLYCO back-contact modules offer?

30-year product and performance guarantee for maximum investment security.

PRESS

SOLYCO Back-Contact PV-Modules in the press:

PV MAGAZINE

PHOTON

SOLARSERVER

PRESS BOX