pv magazine Highlight: Top Innovation for Solyco: Elegant symbiosis for urban climate and climate protection

- Jun 10, 2025

- 4 min read

18 June 2024, pv magazine

Green roofs are good for the urban climate, and photovoltaics help mitigate climate change. It's good when both come together. This is the case with developments using vertically mounted special modules, which impressed our jury.

Anyone standing on the green roof is initially reminded of the orderly and symmetrical gardens of the Baroque period: the vertical photovoltaic modules form several rows at regular intervals. The green roof stretches uninterrupted between and below them. Here, various elements of sustainability are brought together.

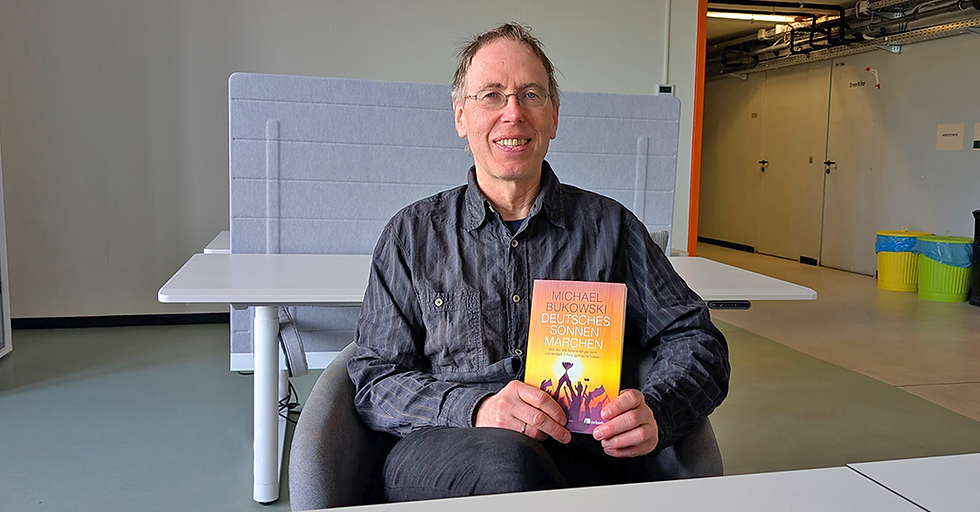

The special-format photovoltaic modules, which are 45 centimeters high and two meters wide and mounted at a 90-degree angle, unusual in this country, are manufactured by Solyco. The company emerged as a management buyout from the research and development company of the formerly well-known module manufacturer Solon under former CTO Lars Podlowski, which ceased production in Germany in 2014.

"We didn't start with a green roof concept, but rather, by installing various test systems since 2017, we explored the advantages of bifaciality and the reflection of light from the brightest possible substrate," says Product Manager Philip Kallenberg. "But then we realized that the vertical installation concept is particularly suitable for green roofs." One reason for this is that it can be installed at a height of 20 centimeters, which allows the plants to grow well. Because it offers a solution to the competition for space between green roofs and photovoltaic systems, the pv magazine jury recognized the system as a Highlight Top Innovation.

This is what the jury says:

Limiting climate change with photovoltaics and improving the urban climate with green roofs: Solyco's solution combines these two important goals. The company has developed specially sized modules that are installed vertically on roofs. The system requires less ballast and leaves more surface area uncovered than conventional systems, allowing it to be installed on existing green roofs. The jury awarded it the pv magazine highlight top innovation award.

The jurors: Volker Quaschning is a professor of renewable energy systems at the HTW Berlin. Hans Urban is a long-time expert and consultant for photovoltaics, storage, and e-mobility. Winfried Wahl heads product management at Longi Solar in Germany.

More information, previous award winners (since 2014) and everything about the application can be found at: www.pv-magazine.de/highlights

Tellingly, the green roof system is called "SOLon." It has been available since last September and, according to the company, has been installed seven times to date, with a total of 100 kilowatts. Solyco thus offers a solution to a trend. According to the German Association for Green Buildings, 10.7 percent more roof areas were greened in 2022 than in the previous year.

Lightweight system thanks to little ballast

"We removed all horizontal elements from the system so that there are no uplift forces," says Philip Kallenberg. However, it is sensitive to lateral pressure forces. "At a wind speed of 130 kilometers per hour, we have a wind pressure on the module of around 1920 Pascal," says Kallenberg. Nevertheless, less ballast is needed to hold the system in position than with conventional ballasted flat roof systems. At a maximum of 22 kilograms per square meter, the system is lighter overall. This simplifies installation and offers the possibility of installing a solar system on green roofs and flat roofs with a low reserve load, says the expert. This is often a problem, especially with older buildings. The low weight also simplifies retrofitting on existing green roofs, since removing the green roof is not necessary, he says.

The modules, each 45 centimeters high, are positioned at a row spacing of 80 centimeters, so that only minimal shading occurs at sunrise and sunset.

Solyco isn't trying to compete directly with conventional systems, which are usually installed at an angle of 15 to 30 degrees. With the new system, the company claims, a nominal output of 100 watts peak per square meter can typically be installed. That's about half that of an east-west orientation with a similar specific yield. "In discussions with customers, we notice that anyone who wants to install a green roof doesn't want to cover it with solar modules," says Kallenberg. "Green roofs aren't fully covered anyway, so we can compete with other systems here."

In addition, the vertical orientation of the modules offers a yield that better suits the usage behavior of many system owners than south-facing modules: "When the sun is vertical at midday, conventional systems generate a lot of solar energy," says Kallenberg. "But the energy is needed in the morning and afternoon when people are at home. Our system has its peaks at precisely these times."

Kallenberg also cites further advantages: While flat-mounted systems are prone to soiling of the front glass, this is not the case with vertical systems. Even in winter, with snow depths of up to 20 centimeters, there is no risk of shading. "When the snow reflects heavily, the power yield is even particularly high," says Philip Kallenberg.

Wind as a challenge

Solyco isn't the first company to explore vertical mounting. It's a much-discussed concept in agri-photovoltaics. The Norwegian solar technology provider Over Easy Solar also offers vertical systems for flat roofs.

Andreas Beinert, team leader for Finite Element Methods at the Fraunhofer Institute for Solar Energy Systems ISE, has also already looked into vertical mounting. "Snow loads are practically negligible," he says. "Depending on the gap to the ground, there is no snow cover in winter, and the snow can even lead to higher yields due to the higher albedo." But the vertical angle of the modules also presents challenges: "Vertically installed modules offer a larger surface area for wind to attack and can therefore lead to higher wind loads. This has an impact on the mounting. It must be able to absorb the loads. The ballasting or anchoring can also be correspondingly more substantial," he explains. According to the expert, this could be a reason for reducing the module size.

The research project "Vertical.solar" investigated this using CFD simulations and wind tunnel measurements. "It was found that with a sufficiently small module area and low mounting, ballasting can even be dispensed with," says Beinert. "However, this depends very much on the selected module size and mounting system."

Solyco says it has optimized the system in this regard by using a double-glazed laminate made of two 3.2-millimeter-thick glass panels for the modules. "Additional stiffening is achieved by an aluminum profile, which also protects the glass edges against mechanical damage, such as hail," explains Philip Kallenberg. (Stefanie Schweizer)